Collection: Safety storage cabinets

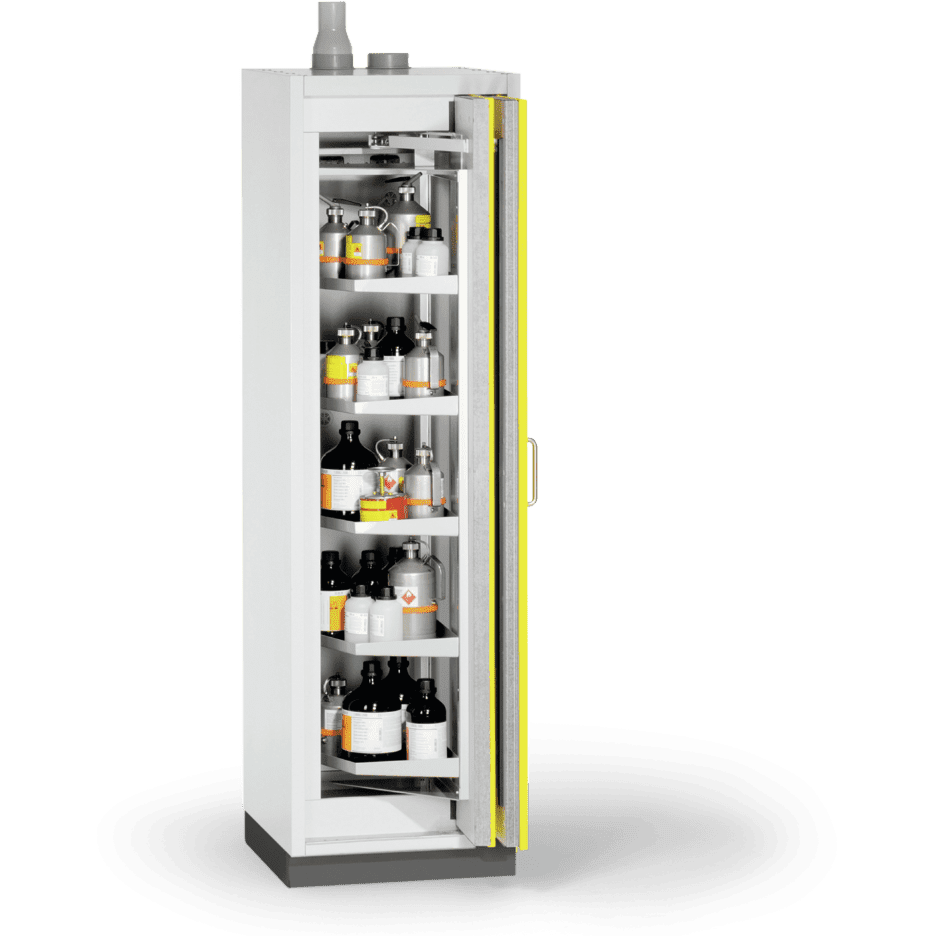

Safety storage cabinets for flammable liquids. High quality safety cabinets for your chemicals with maximum fire protection. Gives valuable time for first extinguishing the fire and evacuation in case of emergency. Maximum security with tested Type 90 technology and automatic self-closing in case of fire.

-

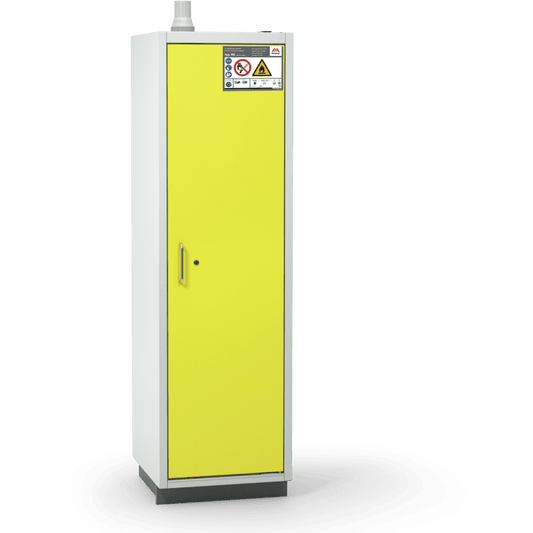

Fire safety cabinet Type 90 CLASSIC standard M 60 cm

Vendor:DüperthalRegular price €2.308,00Regular priceUnit price / per€2.308,00Sale price €2.308,00 -

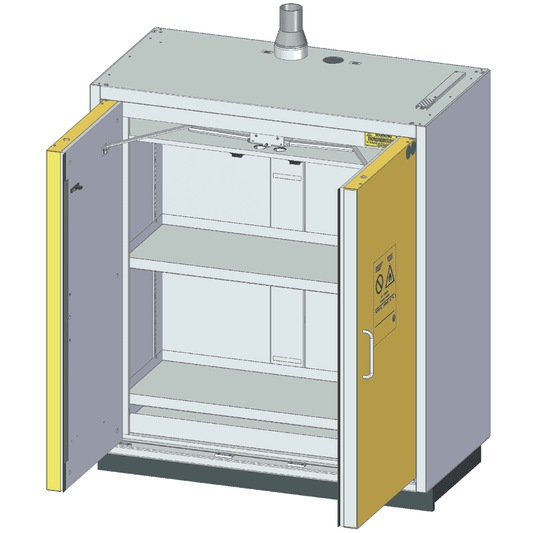

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard M, Düperthal

Vendor:DüperthalRegular price €1.988,00Regular priceUnit price / per€1.988,00Sale price €1.988,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard M-5, Düperthal

Vendor:DüperthalRegular price €2.197,00Regular priceUnit price / per€2.197,00Sale price €2.197,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard S, Düperthal

Vendor:DüperthalRegular price €1.562,00Regular priceUnit price / per€1.562,00Sale price €1.562,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard S-5, Düperthal

Vendor:DüperthalRegular price €1.562,00Regular priceUnit price / per€1.562,00Sale price €1.562,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard L, Düperthal

Vendor:DüperthalRegular price €2.135,00Regular priceUnit price / per€2.135,00Sale price €2.135,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard L-5, Düperthal

Vendor:DüperthalRegular price €2.135,00Regular priceUnit price / per€2.135,00Sale price €2.135,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard XL-5, Düperthal

Vendor:DüperthalRegular price €2.742,00Regular priceUnit price / per€2.742,00Sale price €2.742,00 -

Under-Bench Type 90 Safety Storage Cabinet – UTS Standard XL, Düperthal

Vendor:DüperthalRegular price €2.742,00Regular priceUnit price / per€2.742,00Sale price €2.742,00 -

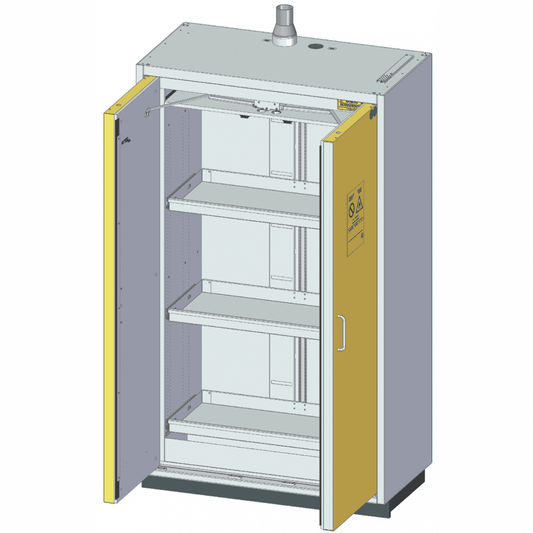

Fire safety cabinet Type 90 CLASSIC standard SL 60 cm

Vendor:DüperthalRegular price €2.297,00Regular priceUnit price / per€2.297,00Sale price €2.297,00 -

Fire safety cabinet Type 90 CLASSIC standard S 60 cm

Vendor:DüperthalRegular price €2.030,00Regular priceUnit price / per€2.030,00Sale price €2.030,00 -

Fire safety cabinet Type 90 CLASSIC standard ML 60 cm

Vendor:DüperthalRegular price €2.526,00Regular priceUnit price / per€2.526,00Sale price €2.526,00 -

Fire safety cabinet Type 90 CLASSIC pro ML 60 cm

Vendor:DüperthalRegular price From €3.075,00Regular priceUnit price / per€3.075,00Sale price From €3.075,00 -

Fire safety cabinet Type 90 CLASSIC pro M 60 cm

Vendor:DüperthalRegular price From €2.779,00Regular priceUnit price / per€2.779,00Sale price From €2.779,00 -

Fire safety cabinet Type 90 PREMIUM standard XL 120 cm

Vendor:DüperthalRegular price From €3.596,00Regular priceUnit price / per€3.596,00Sale price From €3.596,00 -

Fire safety cabinet Type 90 PREMIUM pro M 60 cm

Vendor:DüperthalRegular price From €2.957,00Regular priceUnit price / per€2.957,00Sale price From €2.957,00 -

Fire safety cabinet Type 90 CLASSIC pro L 90 cm

Vendor:DüperthalRegular price From €3.319,00Regular priceUnit price / per€3.319,00Sale price From €3.319,00 -

Fire safety cabinet Type 90 CLASSIC standard XS 120 cm

Vendor:DüperthalRegular price €2.926,00Regular priceUnit price / per€2.926,00Sale price €2.926,00 -

Fire safety cabinet Type 90 CLASSIC pro XL 120 cm

Vendor:DüperthalRegular price From €3.551,00Regular priceUnit price / per€3.551,00Sale price From €3.551,00 -

Fire safety cabinet Type 90 PREMIUM standard M 60 cm

Vendor:DüperthalRegular price €2.701,00Regular priceUnit price / per€2.701,00Sale price €2.701,00

Safety storage cabinets - EN 14470-1

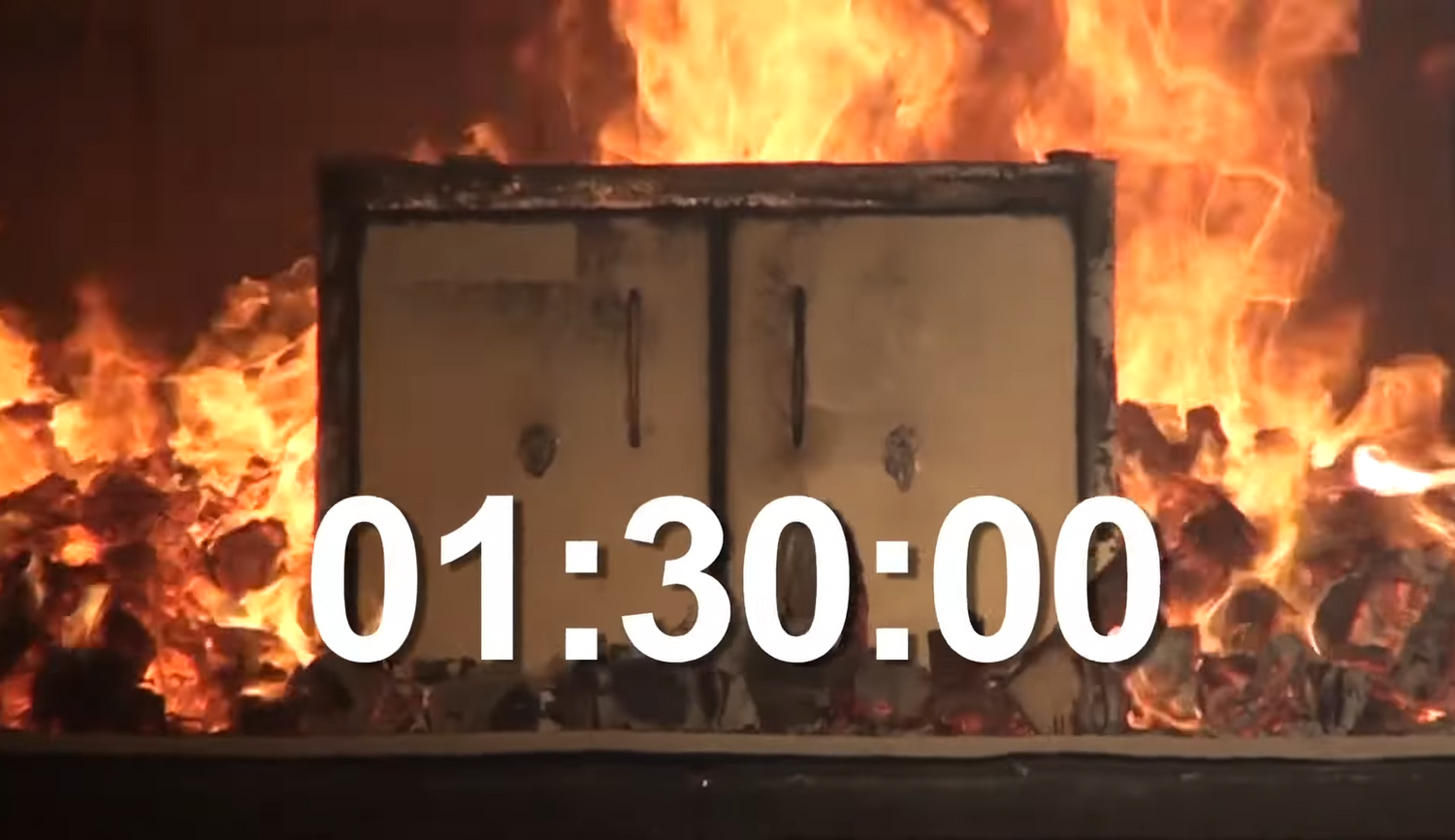

Düperthal safety storage cabinets with Type 90 fire resistance rating allow sufficient time for workers to leave the room in the event of a fire and allow fire fighters sufficient time to get into the laboratory. All of this before a small and extinguishable fire from stored flammable substances can cause an uncontrollable fire. The cabinet is tested under fire conditions as standard. Each cabinet model is type-tested in a fire chamber in accordance with DIN EN 14470-1.

Fire chamber test in accordance with DIN EN 14470-1

The fire resistance rating of safety storage cabinets in accordance with DIN EN 14470-1 is determined by the rise in temperature of the cabinet interior inside a fire chamber, based on the temperature/time curve set out in DIN EN 1363-1. Based on an initial temperature of 20 +/- 5 °C and the time it takes for the temperature in the cabinet interior to reach max. 180 °C, the cabinet is then classified as Type 15, 30, 60 or 90 (corresponding to the time in minutes). Safety storage cabinets for pressurised gas cylinders complying with DIN EN 14470-2 are subjected to a comparable test, see here for details.

Highest fire protection for your safety

Maximum security with Type 90 technology and automatic self-closing in case of fire.

Upscale design for your health

Ventilation and venting at every cabinet level with visual inspection of the shut-off dampers, with continuous earthing concept as standard.

Increased lifetime for your investment

Endurance test in accordance with DIN EN 14727 or newly DIN EN 16121 and DIN EN 16122, even 80,000 instead of 50,000 cycles in the dynamic load test.

Test criteria, protection and minimum requirements

The three essential requirements for a safety storage cabinet in accordance with DIN EN 14470-1 are minimisation of the risk of fire, minimisation of fumes released into the work environment, and retention of possible leakages. The test requirements of the laboratory furniture standard DIN EN 14727 or the new DIN EN 16121 and DIN EN 16122 also guarantee a minimum level of quality.

Extracts from DIN EN 14470-1

NOTE: Remember the differences between FM/UL, NFPA 30 and EN standards

Ventilation

- To prevent an explosive atmosphere, the ventilation must be effective directly above the bottom tray.

- Ventilation openings for air supply and exhaust air must automatically close themselves when the temperature reaches 70° C.

Interior fittings

- The bottom tray, which is used to retain potential leakages, must still be functional after the fire resistance test.

- The shelves must be made of non-absorbent material, must hold the permissible load over the duration of the fire and must be a maximum of 1.75 m above the floor.

Door technology

- Complete self-closing of the doors within a maximum of 20 seconds; an arrest system with temperature release at 50 ° C available as an option.

- The closing force between the main closing and opposite closing edge of the door must not exceed 100 Newtons.

- It must be possible to operate each wing of the door with one hand.

- If the doors are lockable, the locking mechanism must not prevent self-closing in the event of fire.

Fire chamber test

- Each cabinet model and size is type-tested in a fire chamber in accordance with DIN EN 14470-1 Type 90.

Special design

The doors and the outer carcass are made of powder-coated sheet steel.

- The inner carcass and the inside of the doors are made of high-quality decor panels.

- There is a special insulation between the inner and outer carcasses, so that the heat cannot penetrate into the cabinet interior in case of fire.

- In case of fire, doors, drawers and ventilation openings for the air supply and exhaust air are automatically closed and the door gaps as well as open joints are sealed by foam-forming seals.

Video - Type 90 Safety Cabinet in 90 Minute Fire Endurance Test (EN) - DÜPERTHAL

Why to use safety storage cabinet?

Prevents exceeding the self-ignition point

Prevents the risk of an explosive air-gas mixture

Time to extinguishing the fire

Time to evacuate

Chemicals near the workplace

Less chemicals to transport

Fire department according to requirements

Ergonomics

Easy monitoring of chemical quantities

Space saving

Effective air ventilation

Grounding

Integrated collecting sumps

Tested and certified

Chain reactions are avoided in case of fire

Workers, the fire brigade, and rescue services will be protected.

Maximum fire protection for buildings and systems

Possible reduction of insurance contributions for fire protection is possible

Financial security, e.g. by reducing the risk of default of production and buildings

Meets the requirements for risk management in accordance with ISO 9000 and ISO 14001

Use of High Quality safety storage cabinets conserves resources and strengthens the image of your company

Do you need more?

Let's discuss: info@lenolab.fi

DEVELOPMENT AND TIMELINE OF A FIRE - 90 MINUTES

START OF FIRE

- The fire alarm is activated

- Evacuation of employees begins

5-10 min after start of fire

- Employees are outside the danger zone

- The fire brigade is on the way to the site

10-15 min after start of fire

- The fire brigade is at the source of the fire

- Safety storage cabinets with a fire resistance of only 10 minutes stop working at this point

- The flammable substances are no longer safety stored

- The fire brigade has to fight the fire with a considerably increased risk

- Increased damage can be expected

90 min after start of fire - Advantages

Advantages of 90-minute technology for you

- Type 90 safety storage cabinets continue to function for 90 minutes

- The critical hazardous substances are stored safely for at least 90 minutes

- The fire brigade has considerably more time to extinguish the fire safely

- Reduction of the fire load and minimisation of damage