Pol-Eko

Drying oven with nitrogen blow SLWN 15 - chamber capacity 15 litres

Drying oven with nitrogen blow SLWN 15 - chamber capacity 15 litres

SKU:05-1050-5150-0000001

Couldn't load pickup availability

Estimated delivery time: 4-6 weeks

Warranty: 2 years

Drying ovens with nitrogen blow Pol-Eko SLWN

The European norm ISO 589:2003 Hard Coal – Determination of Total Moisture ensures samples are dried between 105 C – 110 C in a drying oven featuring nitrogen blow possibility with flow equal to about 15x capacity of the oven per hour.

SLWN1 – laboratory oven with dry nitrogen blow system of the chamber; the kit includes connections, valves and a laboratory rotameter (which can be calibrated)

SLWN2 - laboratory oven with dry nitrogen blow system of the chamber; the kit includes connections, valves and a tech rotameter (which cannot be calibrated)

Features:

- temperature range + 5°C above ambient temperature ... +300°C

- chamber capacity 15 liters

- working capacity 15 liters

- quality control protocol at +105°C

- instruction manual in English and menu in various languages

- over temperature protection 2.0 class according to DIN 12880

- open door alarm

- air-flap Ø40 mm

- LAN port and USB port

- access port to enter an external sensor (Ø9 mm) on the left side of the unit

- dry nitrogen blow system of the chamber (the kit includes connections, valves and a laboratory rotameter)

- door lock

- Stainless steel wire shelf (INOX)

- external full doors

- available controllers: Smart

Drying ovens with nitrogen blow are available in 5 chamber sizes from 15 to 245 liters capacity. These units are only available with forced air circulation. The nitrogen bottle is not supplied.

BROCHURES

BROCHURES

Share

Options and accessories for drying oven SLWN 15

-

Pol-Eko INOX wire shelf for CL/SL 15

Regular price €62,00 VAT 0%Regular priceUnit price / per€62,00Sale price €62,00 VAT 0% -

Pol-Eko internal lighting for SL and SR

Regular price €131,00 VAT 0%Regular priceUnit price / per€131,00Sale price €131,00 VAT 0% -

Pol-Eko perforated shelf for CL/SL 15

Regular price €68,00 VAT 0%Regular priceUnit price / per€68,00Sale price €68,00 VAT 0%

Drying ovens with nitrogen blow - Inert gas tests

The European norm ISO 589:2003 Hard Coal – Determination of Total Moisture ensures samples are dried between 105 C – 110 C in a drying oven featuring nitrogen blow possibility with flow equal to about 15x capacity of the oven per hour.

Pol-Eko

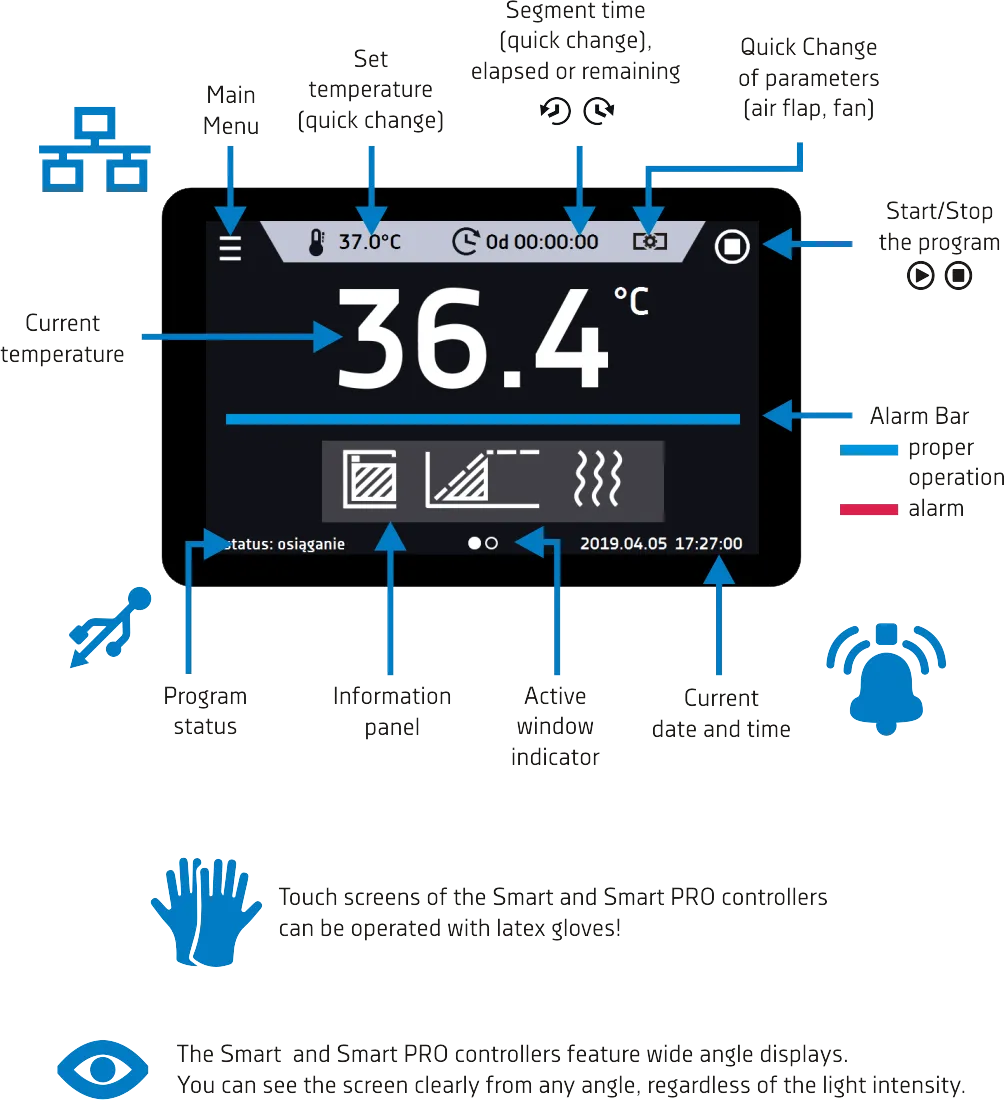

SMART controller

SMART – controller which will be a direct successor of the BASIC and STD (standard) controllers, currently found in the ST cooled incubators, CHL laboratory refrigerators, ZL laboratory freezers, ZLN-UT ultra-low freezers, as well as the IL cooled incubators, CL laboratory incubators,SL drying ovens and SR laboratory sterilizers.

Advantages of the Smart controller:

- 4,3", clear, full colour touch screen

- USB and LAN ports for data transfer

- multi-segment time and temperature programs

- loop function up to 255 times or endless

- adjustable start delay feature

- adjustable ramps

- recording of min, average and max temperature value for each segment

- overview of set and current parameters while operating

- operating in temperature or time priority mode

- fan speed control in the range of 0 … 100% or 10% … 100% (depending on the chamber capacity) except ST/CHL/ZL/ILP

- temperature sensor fail alarm

- possibility of temperature calibration by the User

- power failure control system (program continued after restoring power)

- visual and sound alarm

- internal memory for programs and data storage

- operating with gloves on

- event registry

- user manual for direct download

- ability to buy a license for LabDesk software

- Quick change of program parameters

- Alarm Ba