RADWAG

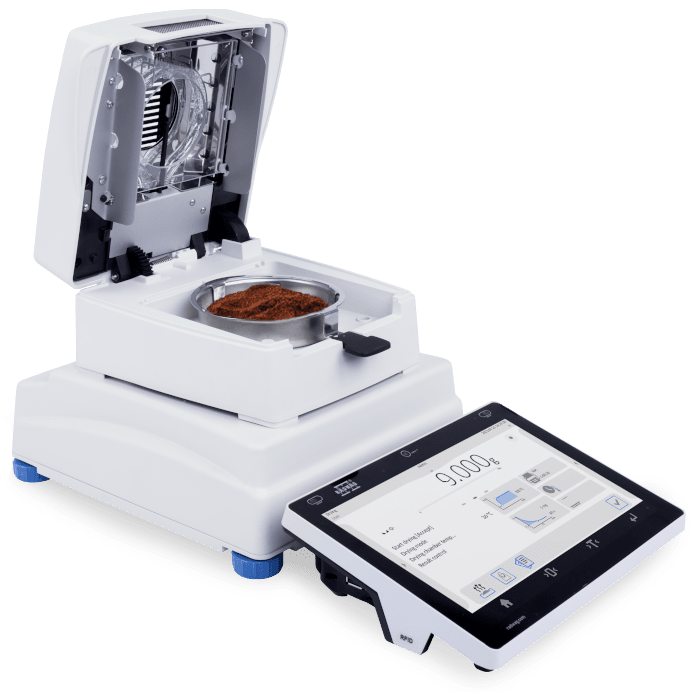

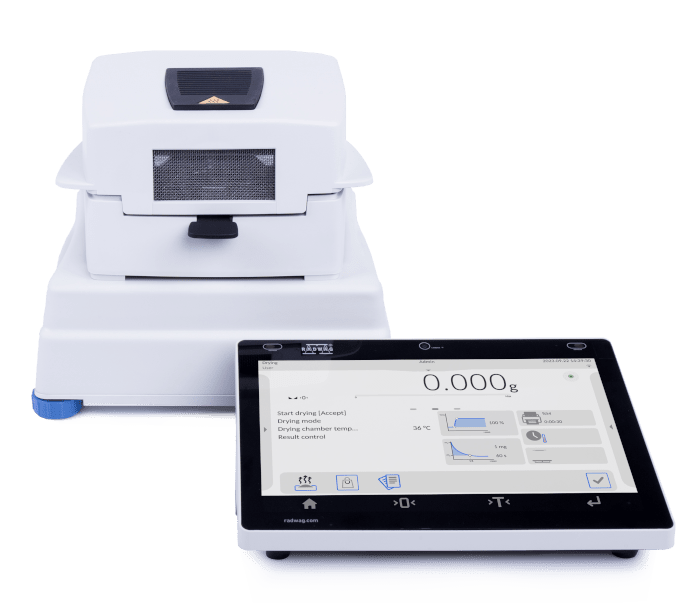

Moisture analyzer MA 5Y

Moisture analyzer MA 5Y

SKU:WL-304-0034

Couldn't load pickup availability

Estimated delivery time: 2-3 weeks

Warranty: 3years

Readability [d]: 0.1 mg - 1 mg

Maximum capacity [Max]: 50 g - 210 g

Share

Options and accessories for moisture analyzer RADWAG MA 5Y -series

-

RS232 cable for RADWAG balances (Balance - PC) - 1,7m

Regular price €23,33 VAT 0%Regular priceUnit price / per

RADWAG

It Dries in 4 Ways

The MA 5Y Moisture Analyzer offers you four drying profiles: standard, mild, fast and step.

- The standard profile is the usually used drying profile. It allows the most accurate determination of moisture content.

- The mild profile is designed for drying substances that are sensitive to the rapid heat released by the filaments, which heat full power at the initial stage of the process. An example of such a substance is leather.

- You will use the fast profile for samples with significant moisture content – of the order of even several tens of percent.

- The step profile will be ideal for drying substances that contain more than 15 percent moisture. Within this profile you can define any three temperatures. You will choose the values of temperature and duration of heating experimentally.

What Drying Temperature Should I Set?

The drying temperature determines the duration of the process. Its value depends on the type of material. If the temperature is too low, it will under-dry the sample and, consequently, unnecessarily increase the measurement time, while if it is too high, it will cause a burning effect on the material. The drying temperature for the traditional (oven) method is determined by industry or factory standards. If there are no standards, you will select the temperature experimentally.

The maximum drying temperature on the MA 5Y Moisture Analyzer is 160°C.

How Do I Finish the Drying? In 4 Ways

The MA 5Y Moisture Analyzer has four finish modes: automatic, manual, time-defined and user-defined.

- Automatic mode

You define the moisture loss limit value in 60 seconds. When the moisture analyzer reaches the set criterion, the measurement will automatically end.

- Manual mode

You terminate the measurement yourself by pressing the STOP button.

- Time-defined mode

The measurement ends after the set time has elapsed regardless of the result. You have up to 99 hours 59 minutes to manage!

- User-defined mode

When you remove all volatiles from a sample, by definition, its mass should be constant. During drying, the dry mass of the sample is defined by a condition: if the mass of the sample is stable within 1 mg during the observation time (Auto 1-5), we consider that all volatile components have been removed from its structure.

Digital Weighing Auditor

Ensures that your balance is ready for use. It enables air buoyancy compensation in real-time. What is more, it informs about the need for a balance inspection or a periodic audit of the balance’s accuracy and sensitivity.

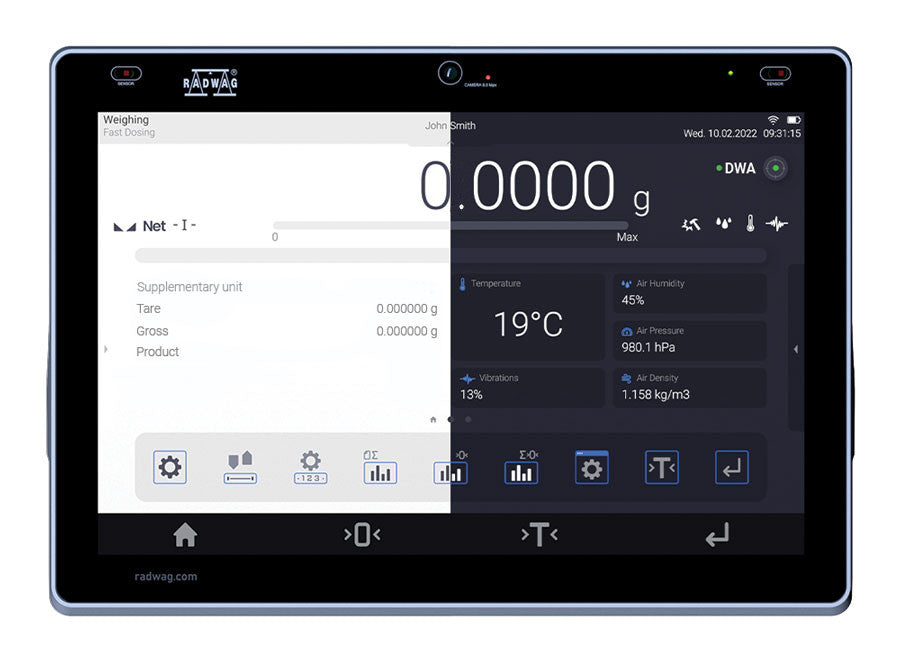

10-Inch Display

Bigger screen –10’’– means more information in one place. On the new ELLIPSIS terminal, you will see up to 3 screens, widgets, graphs, statuses, notes, handy measurement history.

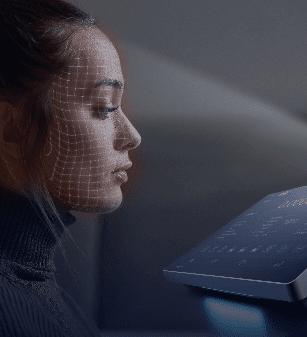

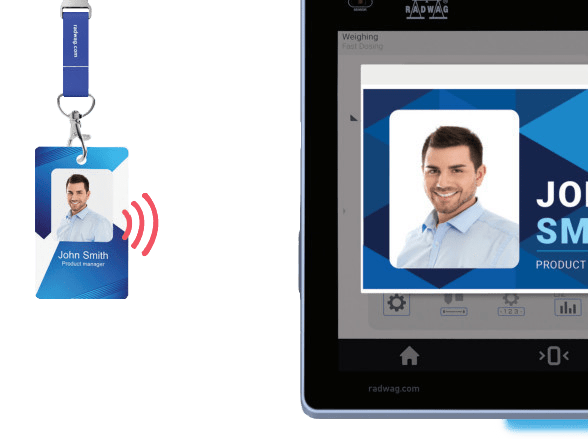

Uncompromising User Verification

For the first time ever, the balance will verify the user using a password, RFID card, fingerprint reader, facial recognition mechanism, or any combination of these.

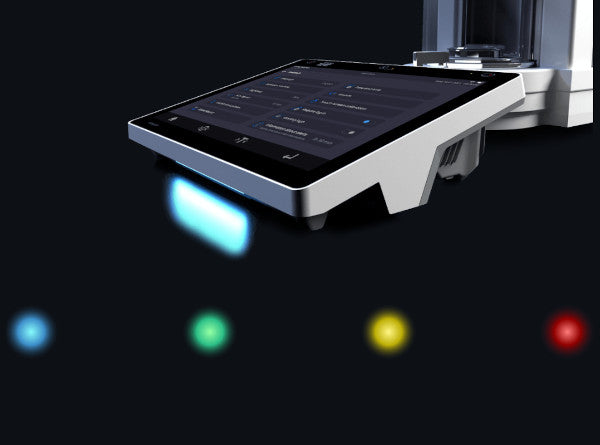

Ambient Light – an Innovative Way for the Moisture Analyzer to Communicate With the User

The light colour will tell you about status, process results, procedures, or alerts.

Hotspot

Use the balance on any device connected to it. This can be a smartphone, tablet, or computer.

RFID

ELLIPSISworks withRFID tags* that can be used to tag your products or formulation ingredients in the database. They can also be used to identify a user.

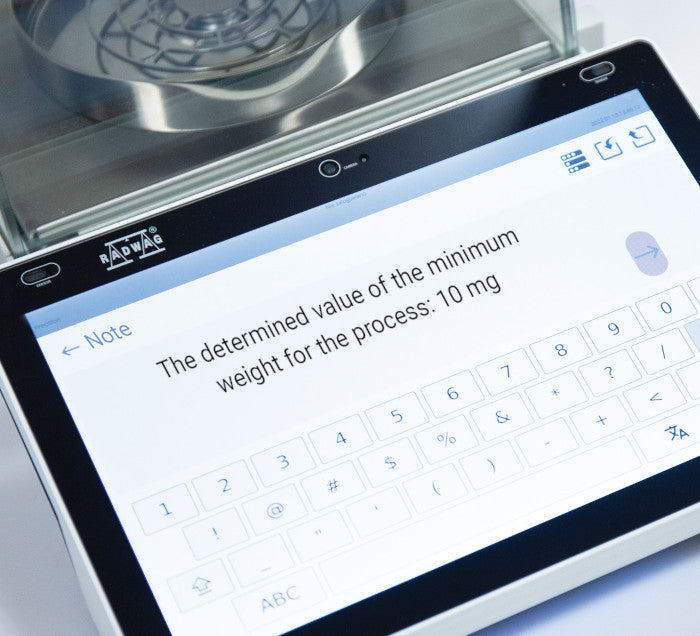

Live Note – Note Down Your Conclusions

It’s the first time you can add a voice memo to a measurement series or procedure report. If you prefer to write it down, ELLIPSIS allows you to add a text note.

Handy Library

This is where a series of recent measurements or a report ready for digital signature, according to 21CFR Part 11, can be found.

Widgets

Prepared to display what you need most at any given moment.

21 CFR Part 11

Do you work in the pharmaceutical industry? Do you need a digital signature?We are offering the laboratory balance which as a standalone fully meets the requirements of 21 CFR Part 11/ EU GMP Annex 11.

- Full data security

- Electronic signatures

- Validations

- Electronic records

- Audit trails

Functions

Autotest

Diagnostic function aiming at metrological parameters determination (repeatability), the parameters are determined for the actual conditions of use. When speaking of repeatability it may be also used for weighing time optimization. Autotest is operated in an automatic mode thus operator’s time is saved.

Statistics

Statistiscs function registers and analyses performed measurements. This supplies the user withthe following information: Max and Min standard deviation, average value, variance, range et.

IR sensors

Programmable function supporting the weighing process through control of the following options: sliding weighing chamber doors, printout, zeroing, tarring etc. Especially appreciated wherever preventing the balance from soiling is important.

GLP Procedures

Diagnostic function allowing to objectively document performed measurements. GLP procedures may be either presented in a short report form or extended one.

Statistical quality control

Statistical control for determination of basic statistical criteria: maximum, minimum, standard deviation, mean values for each batch, etc.

Alibi memory

"ALIBI" memory enables saving and storing up to 100000 measurements. Measurements are saved automatically upon each pressing of the key. There is no need for any additional operations or changing settings.

The following data related with the measurements is saved: measurement date; measurement time; result (mass); tare value; operator carrying out the measurement (logged in); product name.

The software saves the measurement in a so called loop, i.e. when the measurement no. 100001 is saved, the measurement 1 gets automatically deleted from the memory.

Measurements saved to balance memory cannot be deleted.

You can preview and print out the data saved to the ALIBI database.

Drying modes

Method for obtaining maximum drying temperature. There are 4 drying profiles: standard, mild, step, fast. The profiles differ by which ensure various dynamics of temperature increase.

Samples drying

Drying process enables to determine moisture content of a given sample by evaporating its free water and other components. The sample's moisture content [%M] is determined by means of precise weighing carried out before and during the drying process.

Moisture content analysis

Determination of sample's moisture content.

Dry mass determination

Determination of product mass after completed technological, physical and chemical processes enforcing product moisture evaporation. RADWAG moisture analyzers are designed to test the moisture content by heating of the samples, which is done using an IR emitter, a halogen or a metal heater.

Wifi®

Thanks to wireless communication between the computer and a balance, it is possible to use a balance inside a laminar flow hood and a fume cupboard.