RADWAG

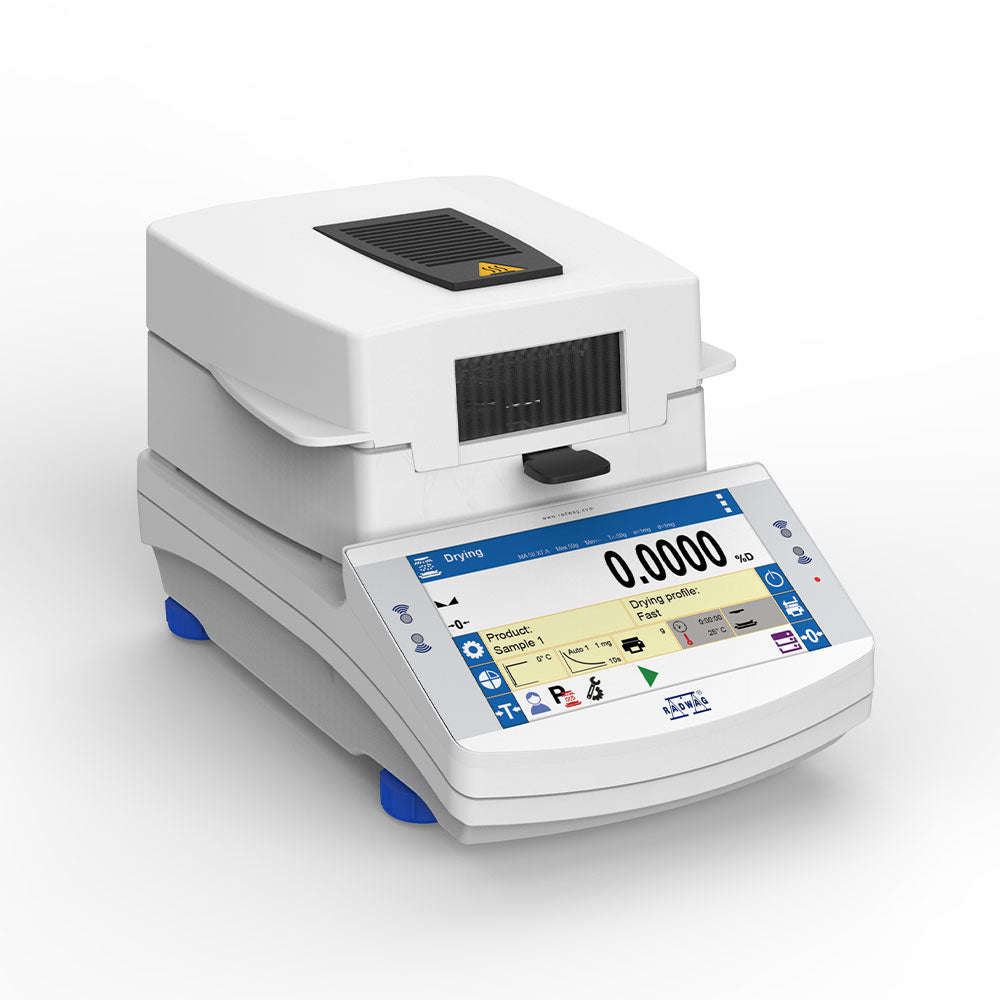

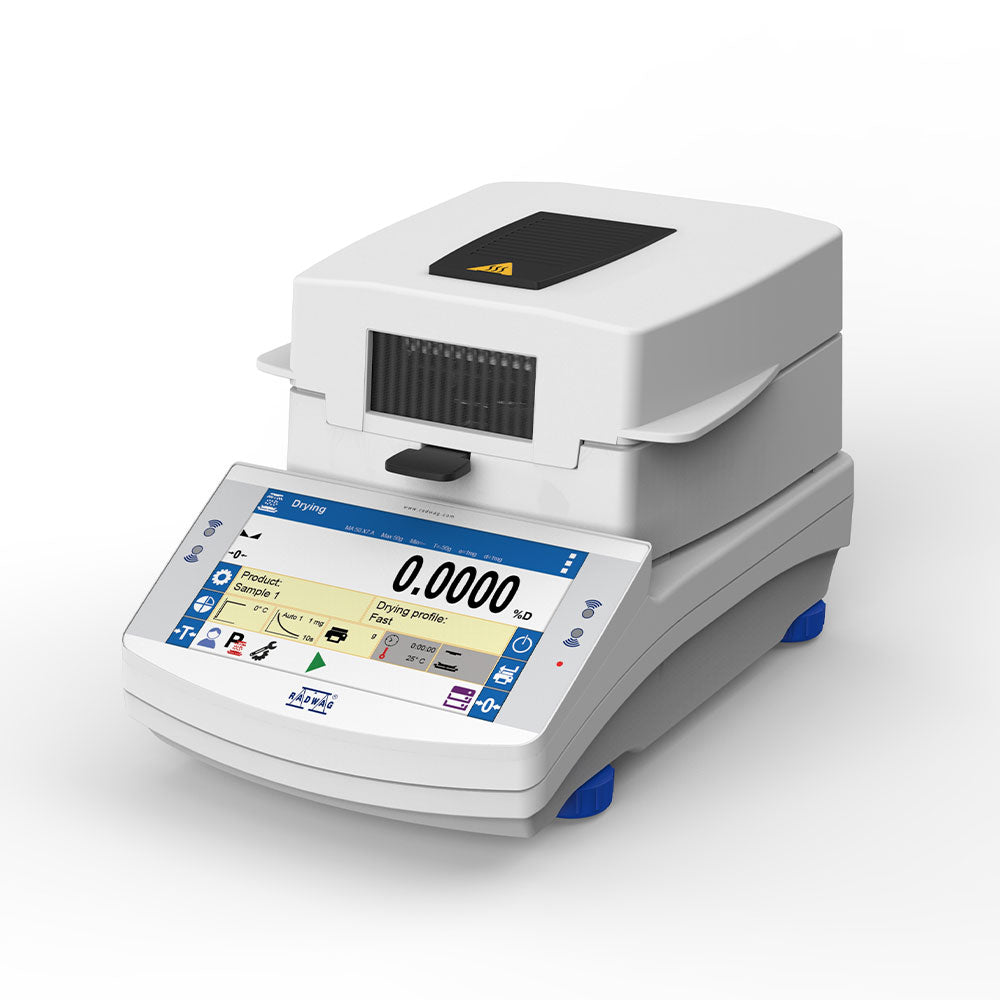

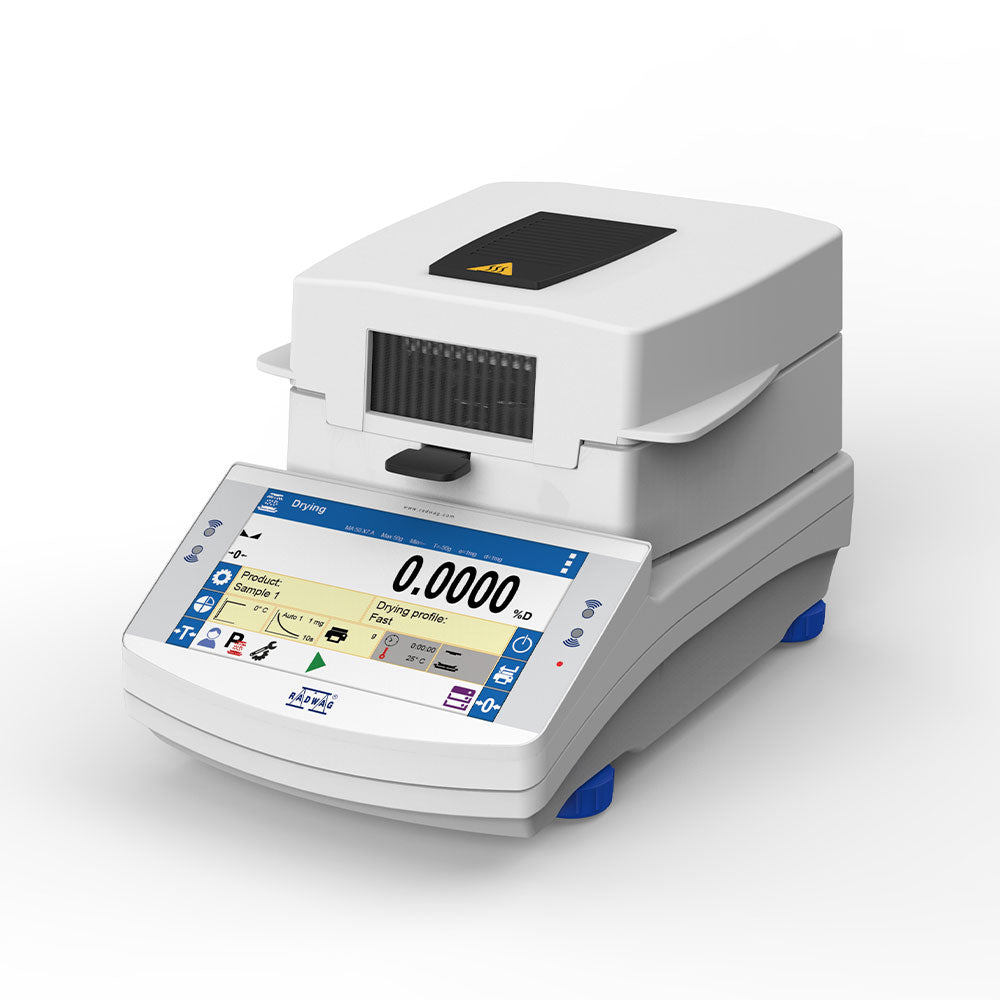

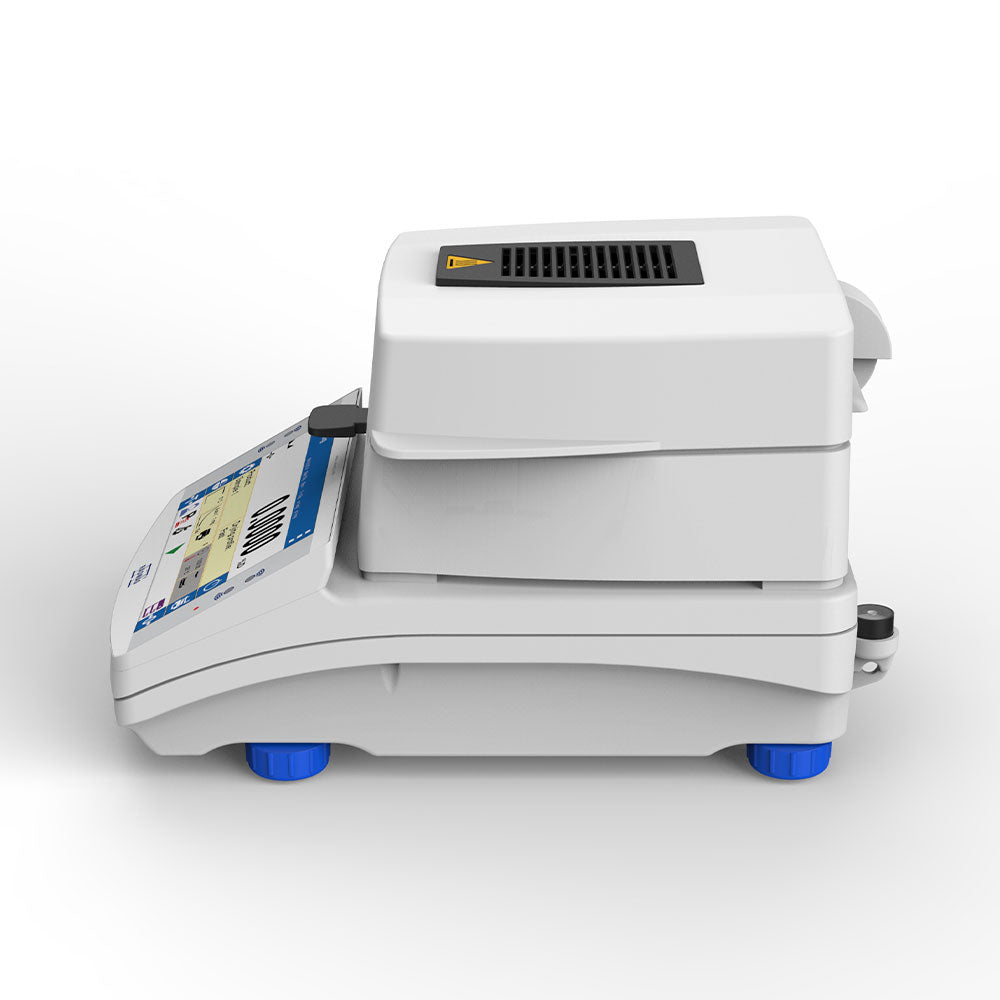

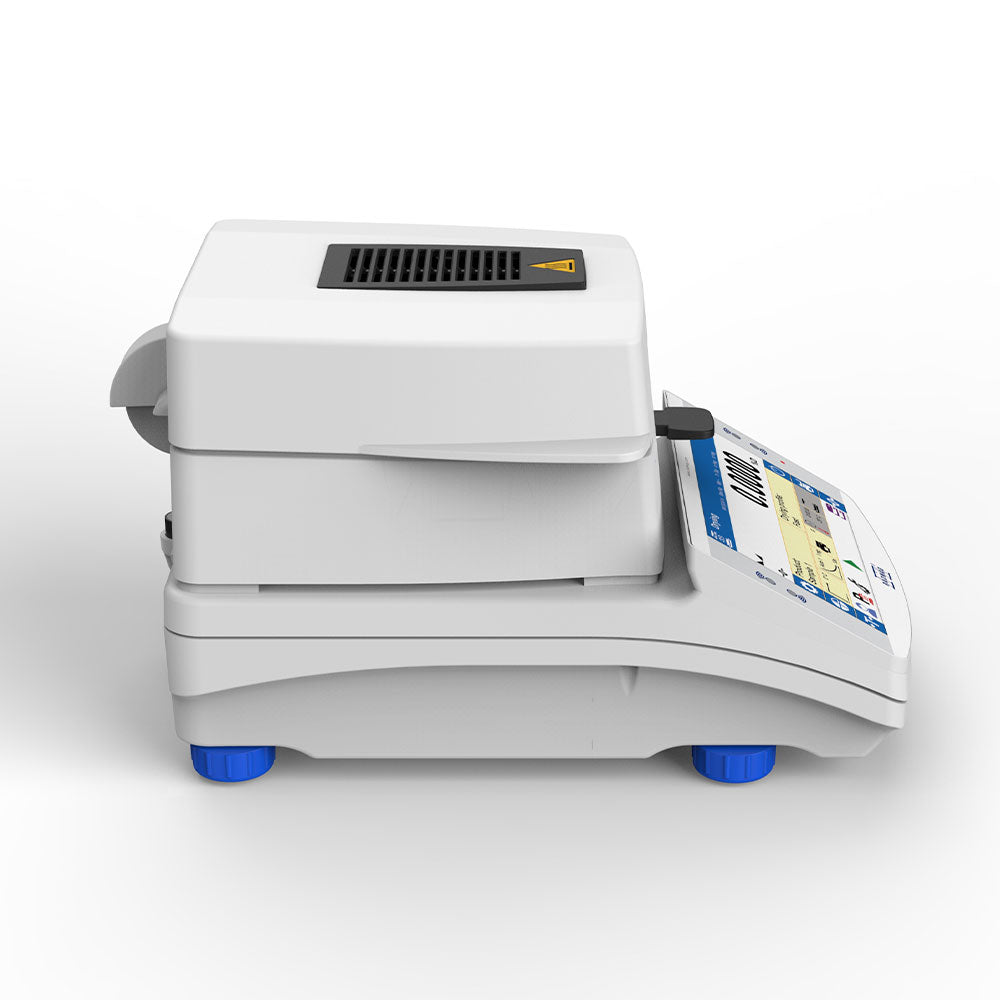

Moisture analyzer MA X7.A

Moisture analyzer MA X7.A

SKU:WL-308-0003

Couldn't load pickup availability

Estimated delivery time: 2-3 weeks

Warranty: 3years

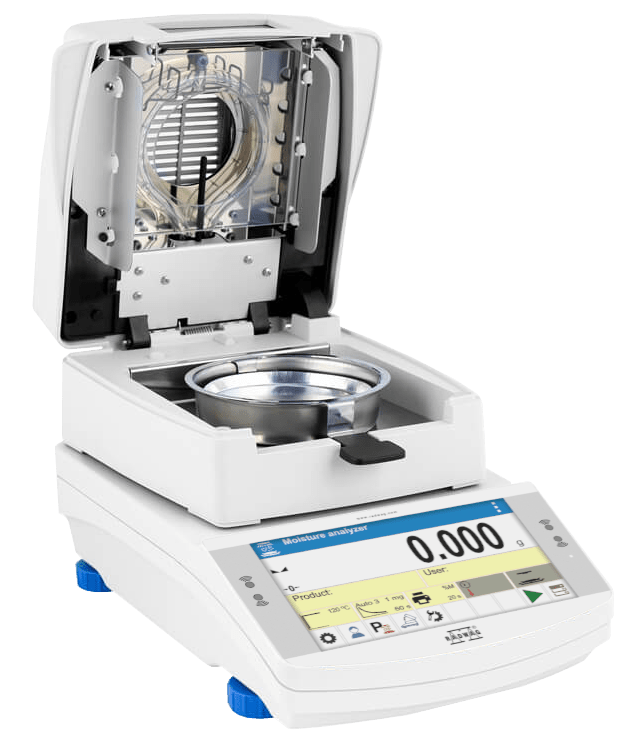

The RADWAG MA X7.A moisture analyzers are hi-tech measuring instruments intended for quick determination of relative moisture content,

dry mass content and other parameters in samples of different substances.

Readability [d]: 0.1 mg - 1 mg

Maximum capacity [Max]: 50 g - 210 g

Share

Options and accessories for moisture analyzer RADWAG MA X7.A -series

-

RS232 cable for RADWAG balances (Balance - PC) - 1,7m

Regular price €23,33 VAT 0%Regular priceUnit price / per

RADWAG

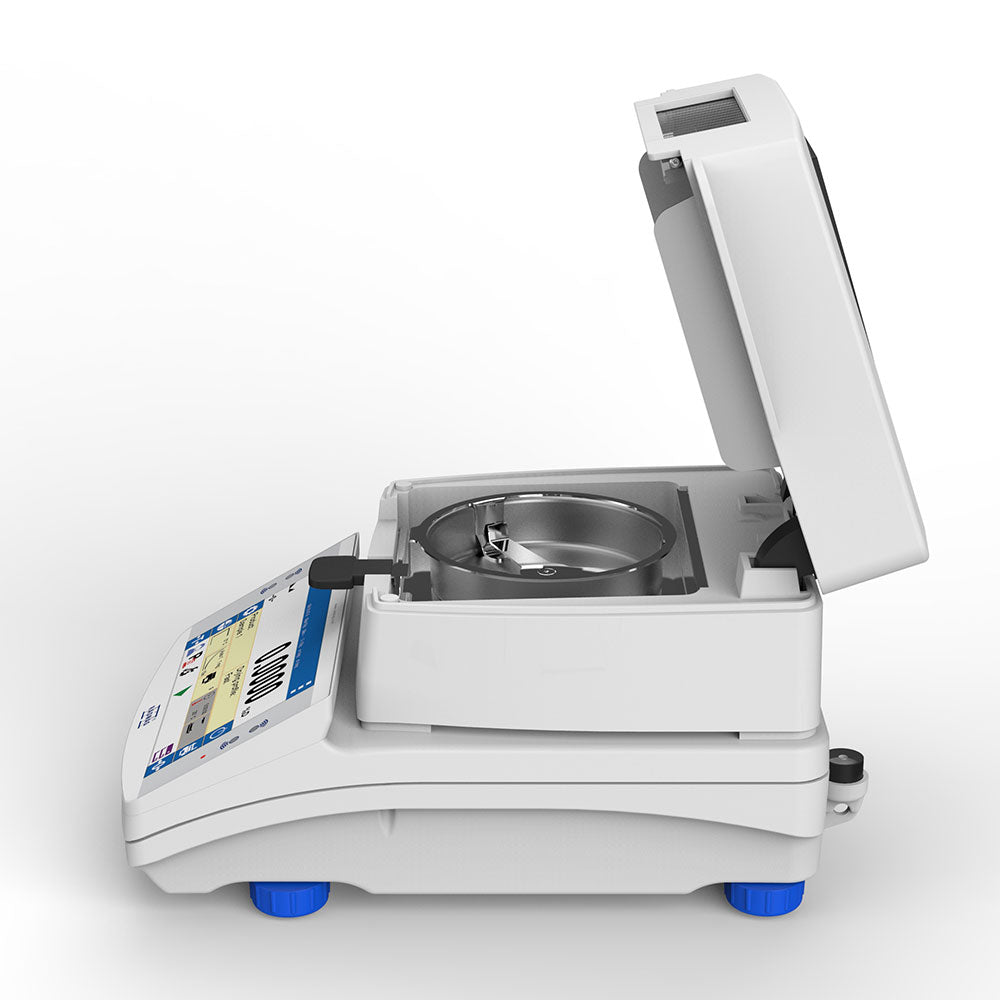

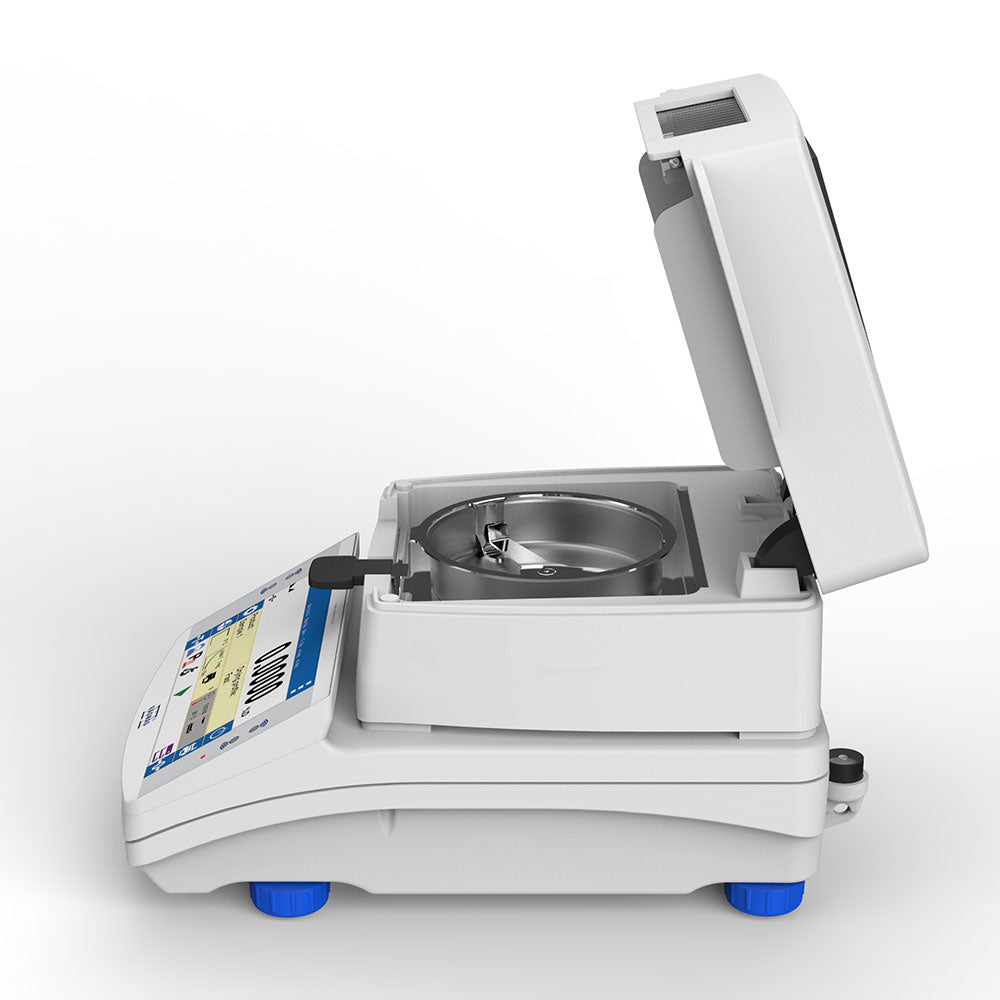

Moisture analyzer MA X7.A

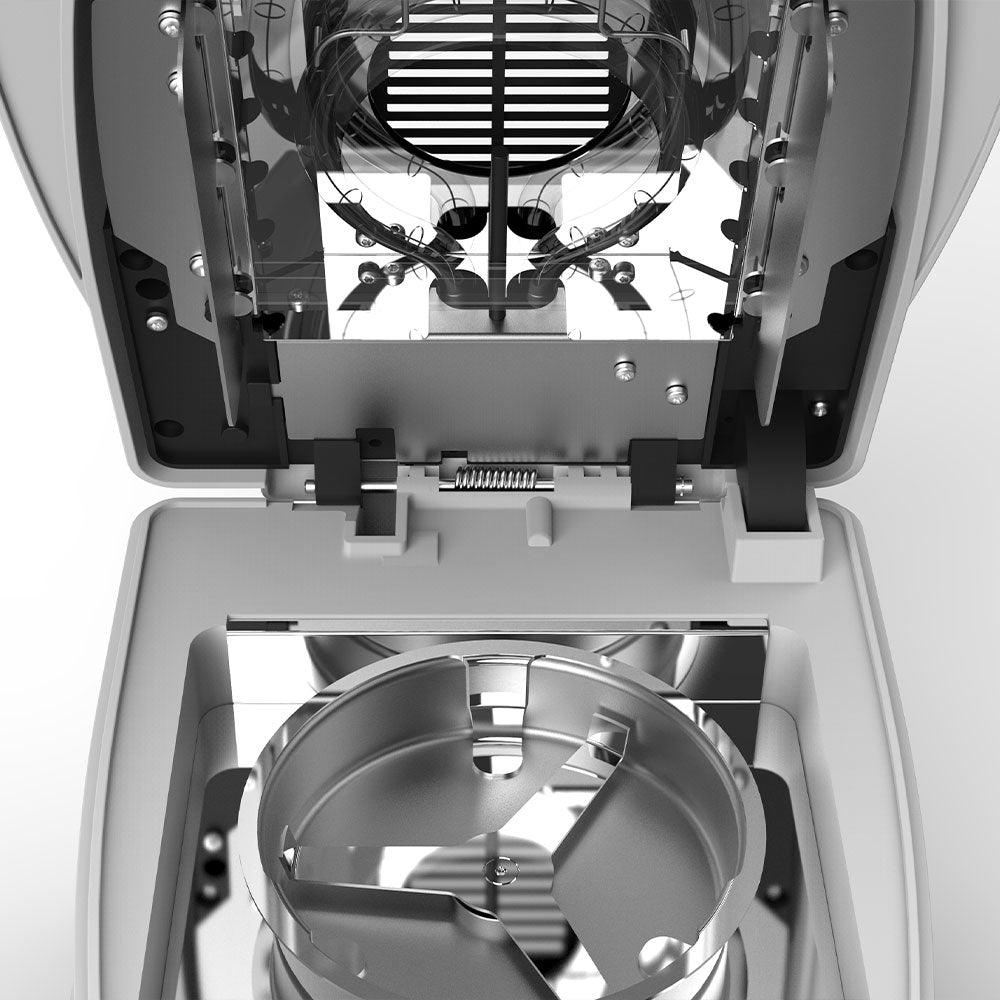

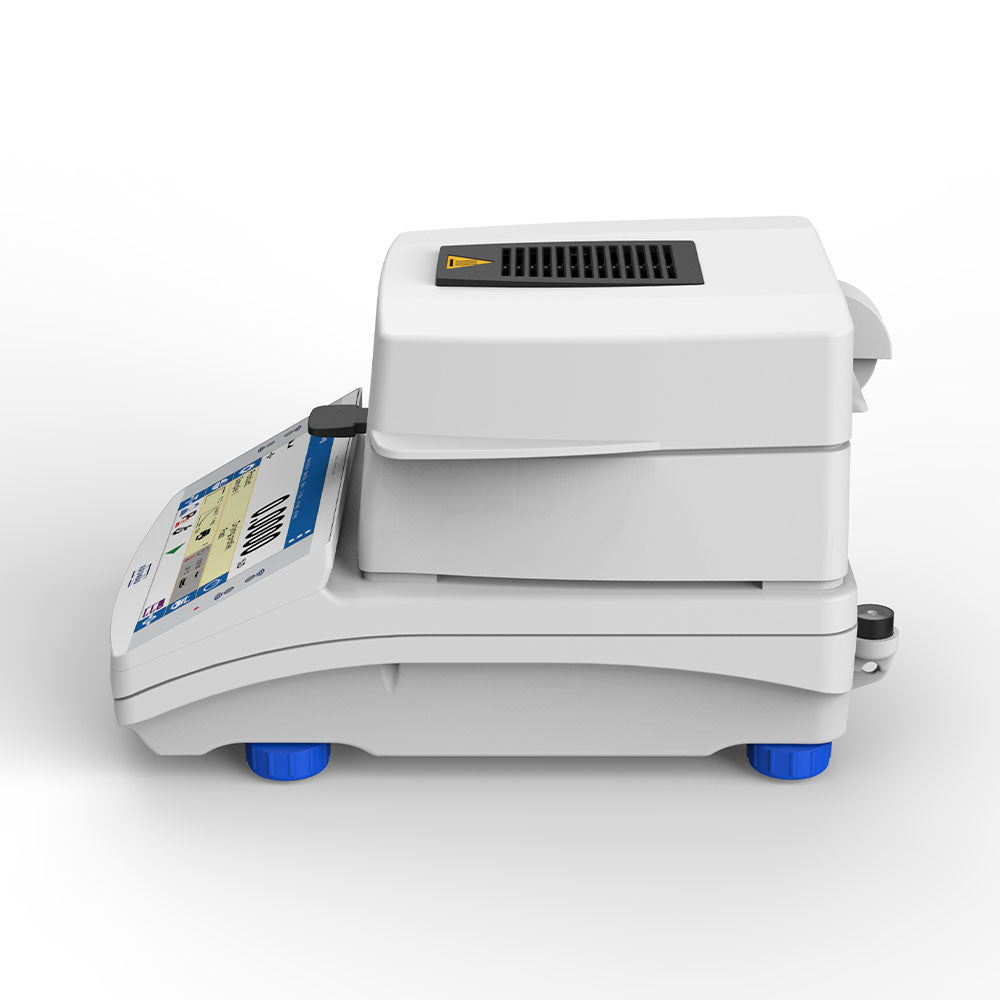

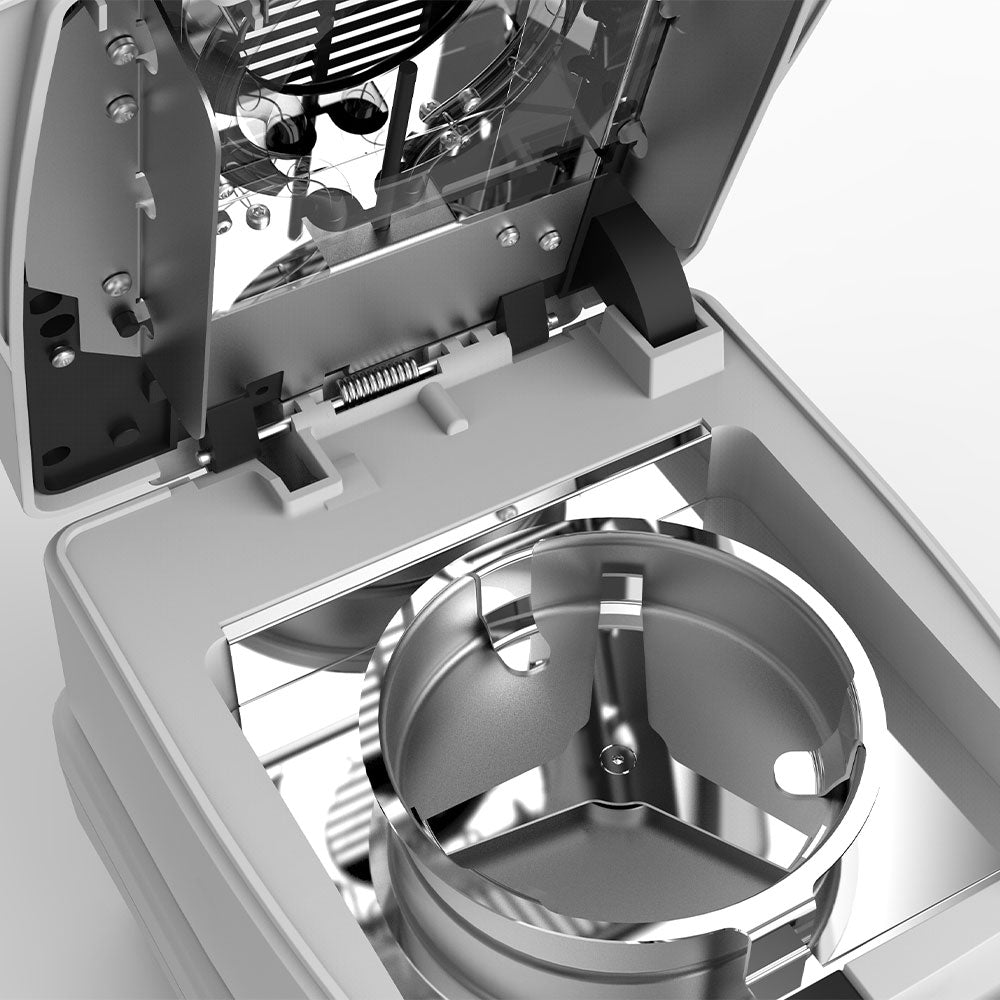

is equipped with innovative system: the drying chamber can be opened and closed automatically using button or proximity sensors.Such solution allows:

- Maintaining moisture analyzer clean – operator does not touch moisture analyzer’s housing.

- Removing any shocks caused by manual closing of the chamber – the chamber closes automatically and always with the same intensity.

- Achieving high repeatability of opening and closing the drying chamber.

- Enhancing drying process automation.

- Enhancing safety of operation by eliminating contact with hot components of drying chamber.

- Improving operation ergonomics.

Highlights of X7 Series moisture analyzers:

- Automatic opening and closing of the drying chamber

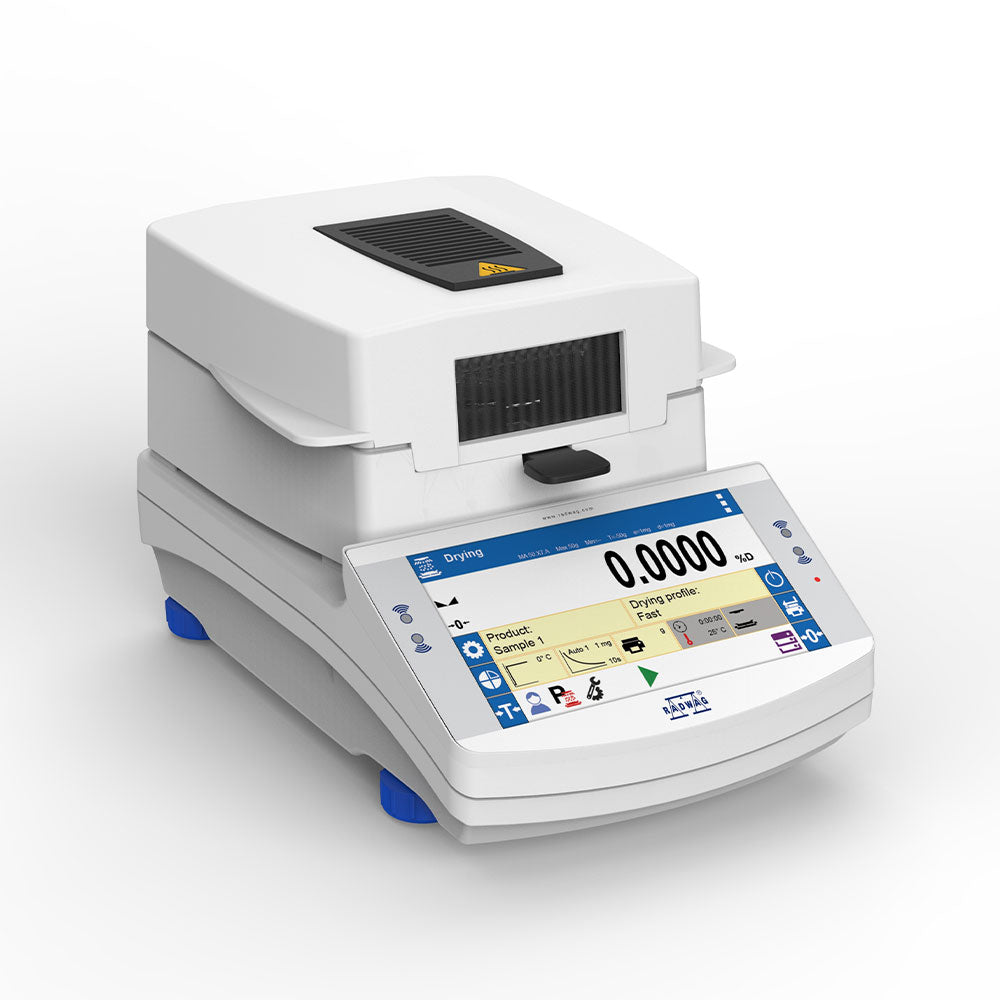

- 7” capacitive colour touchpad

- Modern interface

- Uncomplicated, intuitive operation

- Programmable display

- Drying profiles (standard, mild, step, fast)

- GLP/GMP printouts-reports

- Repeatable and customized applications

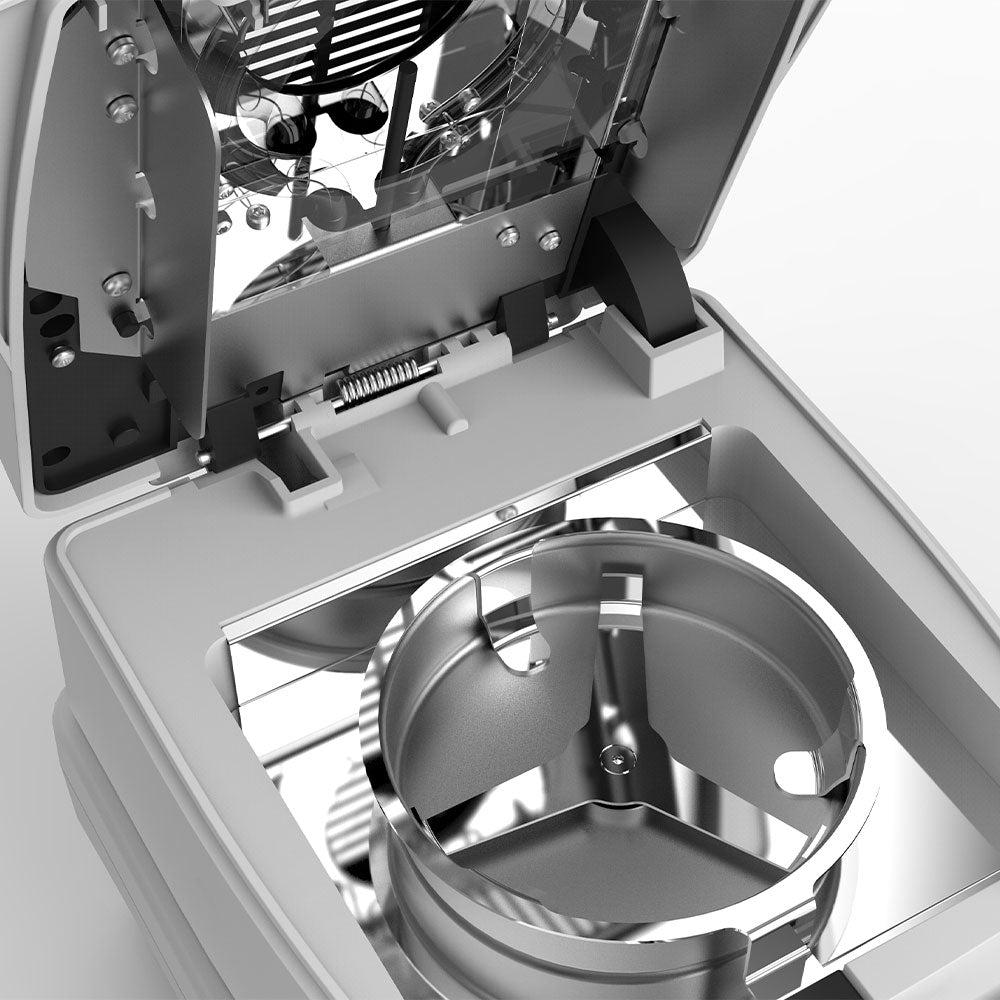

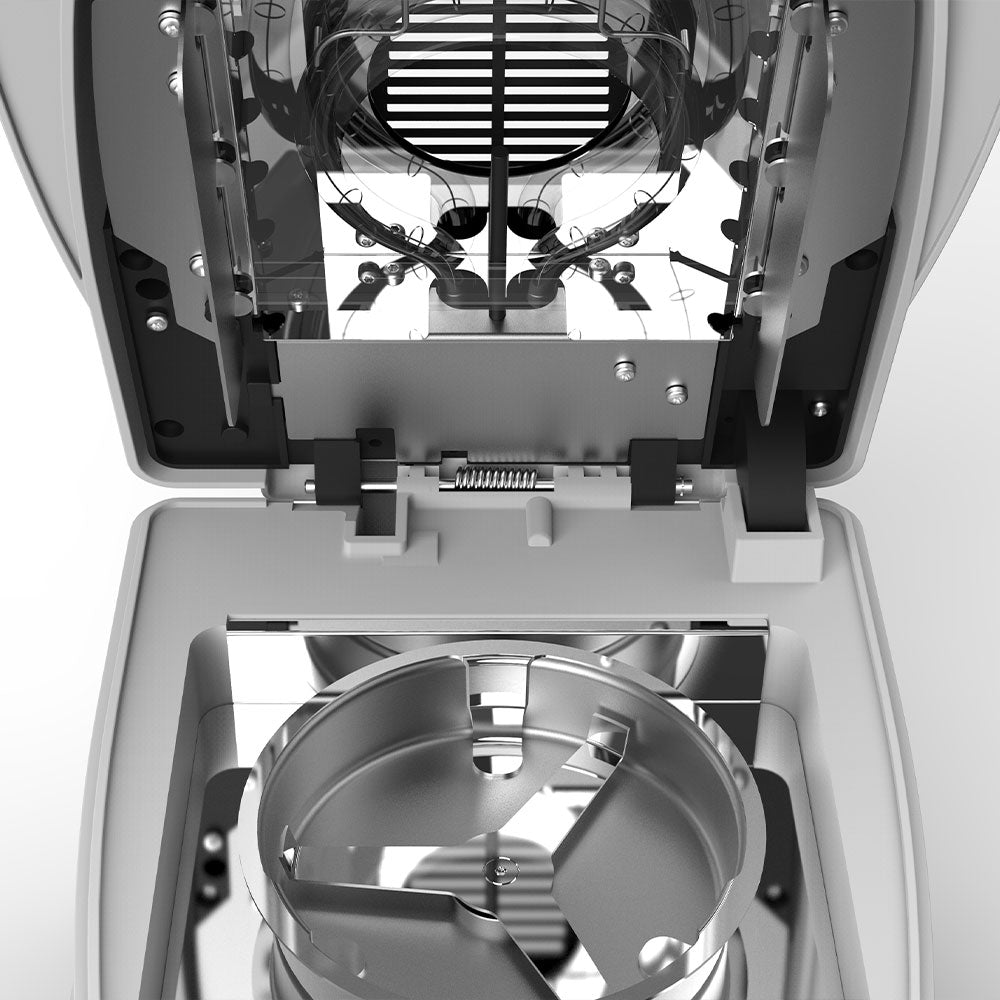

- Work optimization due to the use of halogen lamps

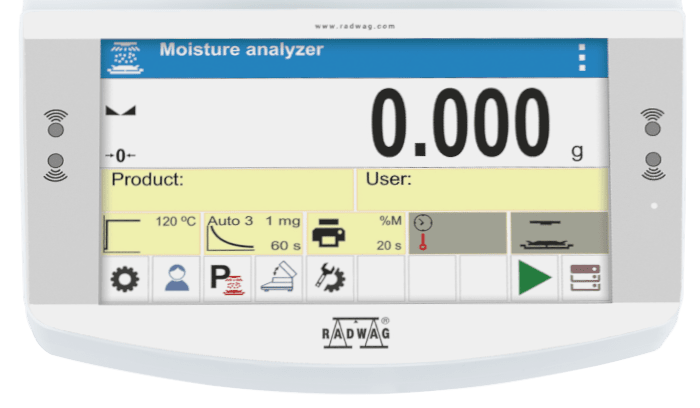

MA.X7.A series features user-friendly colour touchscreen. Free configuration of the control panel can be done by means of hotkeys, customizable information fields and programmable labels. Drying process can be carried out for any temperature and – thanks to databases – particular drying process may be set for a specific product.

Capacity and temperature

MA.X7.A maximum capacity ranges from 50g/0.1mg to 210g/0.1mg. Moisture content is measured with the 0.01%accuracy (0.001 % for samples bigger than 1.5g).The maximum drying temperature is 160˚C(there is an optional moisture analyzer with 250˚C maximum temperature).

An additional element for moisture analyzers that improves their functionality is a water vapour permeability determination set used in tanning industry for determining hygienic properties of leather.

Databases

Information system of X7 series moisture analyzers is based on 8 databases, allowing many users to operate product database comprising many samples. Collected measurements may be subjected to subsequent analysis. Collected data is registered in 8 databases:

- Products (up to 5000 products)

- Users (up to 100 users)

- Packaging (up to 100 packagings)

- Customers (up to 1000 customers)

- Drying programs (up to 200 drying programs)

- Drying process reports (up to 5000 drying process reports)

- Ambient conditions (up to 10000 records)

- Weighings (up to 50000 records)

The results

The results obtained using the moisture analyzer (the final result of the drying process):

- % M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

- % D – the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

- % R – the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

- g – the sample mass after drying.

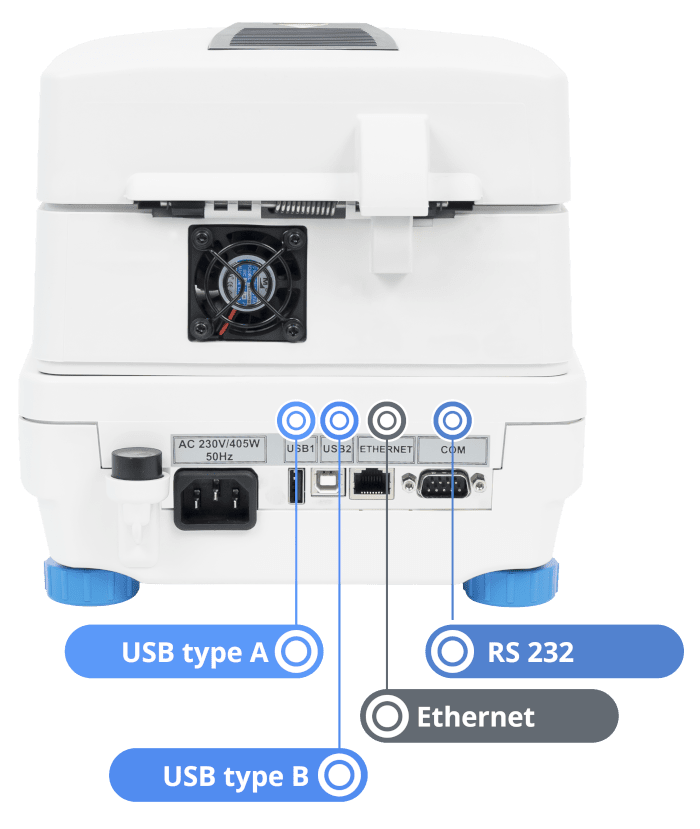

Interfaces

USB interface ensures quick transfer and copying of any results of your work (measurements, reports, databases) to a computer or other moisture analyzer.

Remote access to the moisture analyzer allows for online data management.

Cooperation with E2R allows for external data management which in turn increases the efficiency and results to the maximum.

Functions

Autotest

Diagnostic function aiming at metrological parameters determination (repeatability), the parameters are determined for the actual conditions of use. When speaking of repeatability it may be also used for weighing time optimization. Autotest is operated in an automatic mode thus operator’s time is saved.

Statistics

Statistiscs function registers and analyses performed measurements. This supplies the user withthe following information: Max and Min standard deviation, average value, variance, range et.

IR sensors

Programmable function supporting the weighing process through control of the following options: sliding weighing chamber doors, printout, zeroing, tarring etc. Especially appreciated wherever preventing the balance from soiling is important.

GLP procedures

Diagnostic function allowing to objectively document performed measurements. GLP procedures may be either presented in a short report form or extended one.

Statistical quality control

Statistical control for determination of basic statistical criteria: maximum, minimum, standard deviation, mean values for each batch, etc.

ALIBI memory

"ALIBI" memory enables saving and storing up to 100000 measurements. Measurements are saved automatically upon each pressing of the key. There is no need for any additional operations or changing settings.

The following data related with the measurements is saved: measurement date; measurement time; result (mass); tare value; operator carrying out the measurement (logged in); product name.

The software saves the measurement in a so called loop, i.e. when the measurement no. 100001 is saved, the measurement 1 gets automatically deleted from the memory.

Measurements saved to balance memory cannot be deleted.

You can preview and print out the data saved to the ALIBI database.

Drying modes

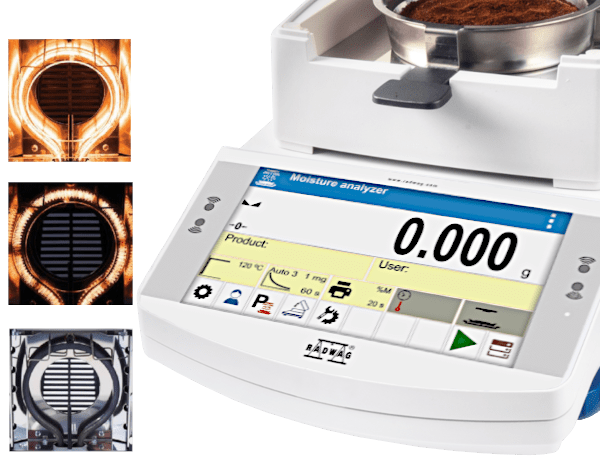

Method for obtaining maximum drying temperature. There are 4 drying profiles: standard, mild, step, fast. The profiles differ by which ensure various dynamics of temperature increase.

Samples drying

Drying process enables to determine moisture content of a given sample by evaporating its free water and other components. The sample's moisture content [%M] is determined by means of precise weighing carried out before and during the drying process.

Moisture content analysis

Determination of sample's moisture content.

Dry mass determination

Determination of product mass after completed technological, physical and chemical processes enforcing product moisture evaporation. RADWAG moisture analyzers are designed to test the moisture content by heating of the samples, which is done using an IR emitter, a halogen or a metal heater.

Wi-Fi®

Thanks to wireless communication between the computer and a balance, it is possible to use a balance inside a laminar flow hood and a fume cupboard.