RADWAG

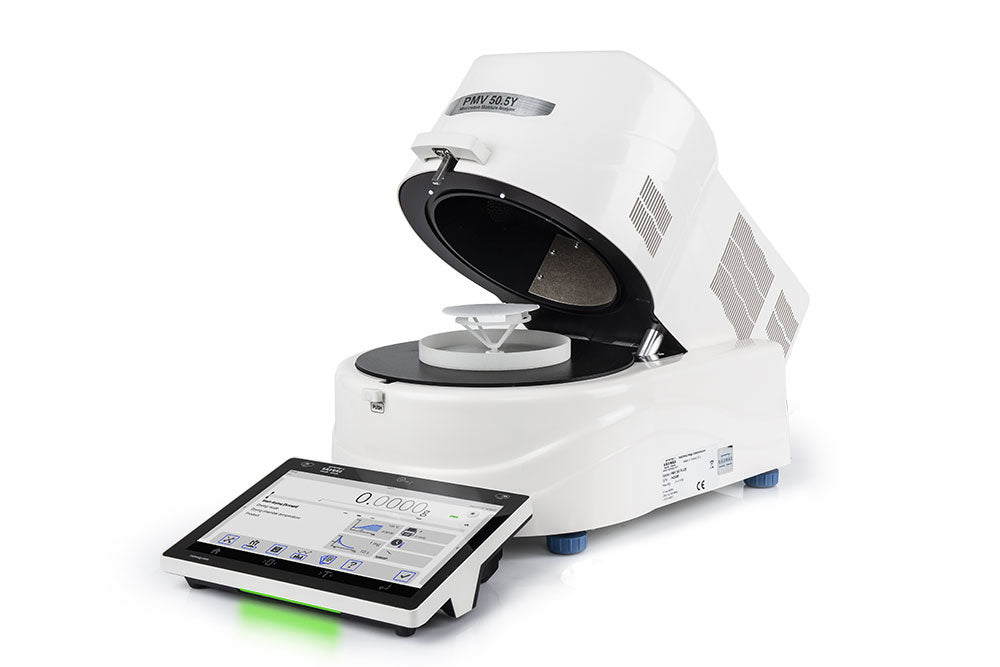

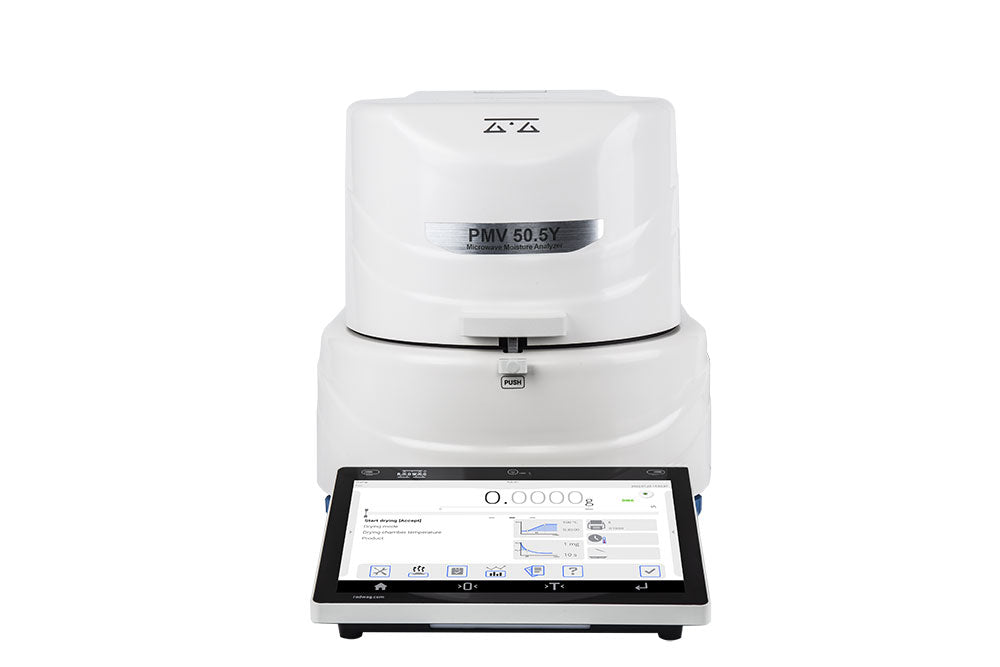

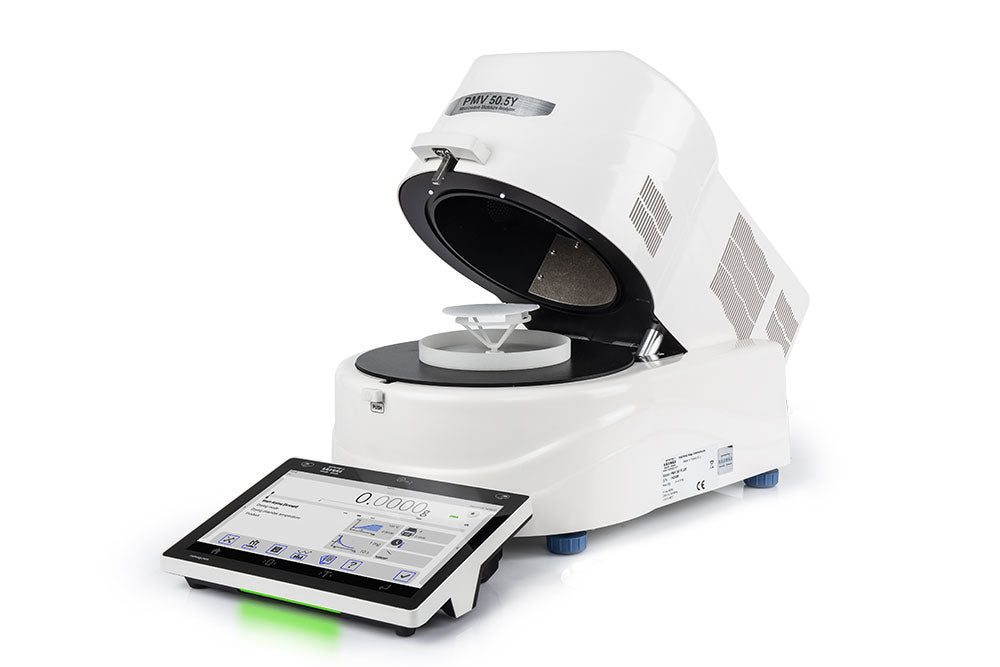

Moisture analyzer PMV 5Y

Moisture analyzer PMV 5Y

SKU:WL-307-0006

Couldn't load pickup availability

Estimated delivery time: 2-3 weeks

Warranty: 3 years

Readability [d]: 0.1 mg

Maximum capacity [Max]: 50 g

Share

Options and accessories for moisture analyzer RADWAG PMV 5Y -series

-

RS232 cable for RADWAG balances (Balance - PC) - 1,7m

Regular price €23,33 VAT 0%Regular priceUnit price / per

RADWAG

Moisture analyzer PMV 5Y

Microwave moisture analyzer can be successfully used wherever materials containing large amounts of water are dried. These materials are, for example, dairy products, fish, meat, fruit products, syrups, creams or liquid resin.

The sample is placed in the drying chamber on a glass fibre filter. At the bottom of the chamber there is one end of the waveguide from where the microwaves are emitted. Upon process start, microwaves are equally distributed on the filter’s surface and dry the sample. The moisture content is determined on the basis of the mass loss obtained during drying.

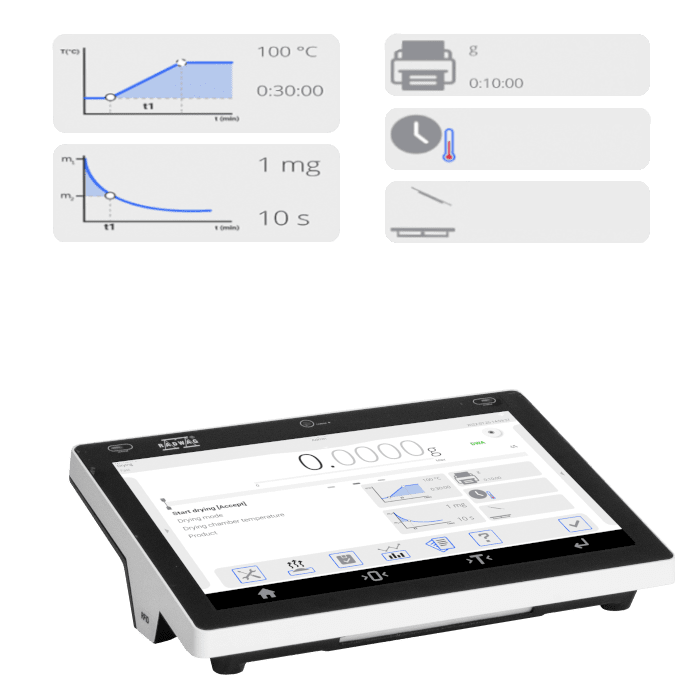

A respective drying program is selected depending on sample mass and its chemical composition. The average duration of this process depends on the type and mass of used substance, and takes 1 to 10 minutes. In contrast, drying using the traditional halogen moisture analyzer takes 5 to 40 minutes.

The PMV 5Y microwave moisture analyzer is equipped with a temperature sensor and enables to monitor device power in order to prevent exceeding the boiling point during the process. A preset microwave power is displayed on the indicator throughout the drying procedure.

The PMV 5Y’s main features:

- intended for drying of samples containing significant amount of moisture (up to 100%),

- ultra-short drying time when compared to traditional moisture analyzers and standard drying methods,

- microwave-based solution,

- uniform heating of entire sample’s surface,

- complex database of drying programs,

- finish mode: manual, automatic, time-defined, user-defined,

- advanced reports, time and statistical graphs,

- easy operation due to a touch screen.

The PMV 50.5Y moisture analyzer is based on an advanced-class Y series system intended for laboratory balances. Expanded 16 GB memory enables saving and storing sophisticated reports and time and statistical graphs. Wireless communication improves ergonomics and operation safety. Wi-Fi®®enables sending data between the moisture analyzer and a mobile device. Large 10’’ touch screen guarantees comfort of operation. Proximity sensors ensure touch-free access to user-specified operations.

For each purchase of the PMV 5Y moisture analyzer the customer is supplied with:

- 60 glass fibre filters of ø90 mm,

- a sample of sodium chloride 10% ± 0,5% to determine correctness of the operation at the workstation,

- a service concerning determination of drying parameters for five customer-selected samples carried out by RADWAG employee.

The results obtained using the moisture analyzer (the final result of the drying process):

% M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

% D– the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

% R– the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

g– the sample mass after drying.

* All trademarks and registered trademarks are the property of their respective owners.

Terminal 5Y in Microwave Moisture Analyzer

With the 5Y terminal, microwave moisture analyzer PMV gain new capabilities and functionalities, such as:

- 10-inch display,

- Digital Weighing Auditor (DWA),

- uncompromised user verification,

- Ambient Light,

- hotspot,

- RFID*,

- Live Note voice and text notes,

- voice commands for the device,

- measurement history within the Handy Library,

- widgets.

Functions

Microwave drying

Drying process enables to determine moisture content of a given sample by evaporating its free water and other components. The sample's moisture content [%M] is determined by means of precise weighing carried out before and during the drying process.

Autotest

Diagnostic function aiming at metrological parameters determination (repeatability), the parameters are determined for the actual conditions of use. When speaking of repeatability it may be also used for weighing time optimization. Autotest is operated in an automatic mode thus operator’s time is saved.

Statistics

Statistiscs function registers and analyses performed measurements. This supplies the user withthe following information: Max and Min standard deviation, average value, variance, range et.

IR sensors

Programmable function supporting the weighing process through control of the following options: sliding weighing chamber doors, printout, zeroing, tarring etc. Especially appreciated wherever preventing the balance from soiling is important.

GLP Procedures

Diagnostic function allowing to objectively document performed measurements. GLP procedures may be either presented in a short report form or extended one.

Statistical quality control

Statistical control for determination of basic statistical criteria: maximum, minimum, standard deviation, mean values for each batch, etc.

Alibi memory

"ALIBI" memory enables saving and storing up to 100000 measurements. Measurements are saved automatically upon each pressing of the key. There is no need for any additional operations or changing settings.

The following data related with the measurements is saved: measurement date; measurement time; result (mass); tare value; operator carrying out the measurement (logged in); product name.

The software saves the measurement in a so called loop, i.e. when the measurement no. 100001 is saved, the measurement 1 gets automatically deleted from the memory.

Measurements saved to balance memory cannot be deleted.

You can preview and print out the data saved to the ALIBI database.

Drying modes

Method for obtaining maximum drying temperature. There are 4 drying profiles: standard, mild, step, fast. The profiles differ by which ensure various dynamics of temperature increase.

Samples drying

Drying process enables to determine moisture content of a given sample by evaporating its free water and other components. The sample's moisture content [%M] is determined by means of precise weighing carried out before and during the drying process.

Moisture content analysis

Determination of sample's moisture content.

Dry mass determination

Determination of product mass after completed technological, physical and chemical processes enforcing product moisture evaporation. RADWAG moisture analyzers are designed to test the moisture content by heating of the samples, which is done using an IR emitter, a halogen or a metal heater.

Wifi®

Thanks to wireless communication between the computer and a balance, it is possible to use a balance inside a laminar flow hood and a fume cupboard.