Pol-Eko

Safety shower test unit, TU

Safety shower test unit, TU

SKU:05-2140-0000-0000001

Couldn't load pickup availability

Estimated delivery time: 4-5 weeks

Warranty: 2 years

Laboratory safety showers should be tested once a month to check the functionality and the requested water flow rate of 60 l/min in an emergency case. This mobile test unit provides a very convenient and easy solution to test your body safety showers and handheld eye showers.

POL-EKO TU SAFETY SHOWER TEST UNIT

- Transparent PVC water reservoir on castors, 120 litre capacity

- Built-in suction pump (230 V) and IP 44 protected power switch

- Drain hose (2 m) to empty the water reservoir

- Separate mounts for drain hose and power cord

Centrally placed under the body safety shower the big funnel can be extended to a height of 2,30 metres, while the smaller funnel is designed to collect the water from handheld eye showers (min. flow rate: 6 l/min). The collected water amount can be read on the water reservoir scale from 0 to 120 litres. The built-in electrical suction pump will empty the reservoir in a very short time.

According to EN 15154-1,2:2006 the water flow rate of the plumbed-in body showers shall be at least 60 l/min and 6 l/min of the plumbed-in eye wash units.

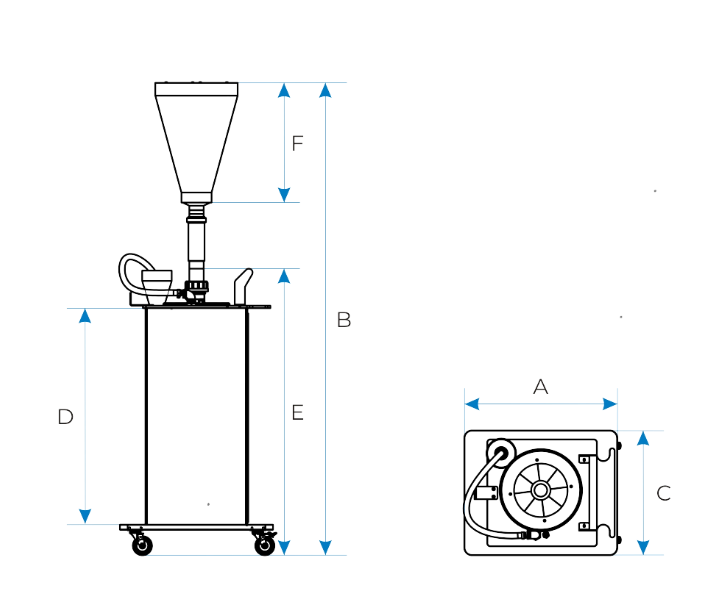

DATA SHEET: POL-EKO SAFETY SHOWER TEST UNIT

BROCHURES

BROCHURES

Data Sheet: Pol-Eko Safety Shower Test Unit

Instruction manual: Pol-Eko Safety Shower Test Unit

Share

Pol-Eko TU - Safety shower test unit

Requirements for emergency showers

How often should emergency showers be tested?

The functionality of an emergency shower can be crucial in the event of an accident. Therefore, regular testing is an essential part of occupational safety. In Finland, national regulations and European standards are applied to define the testing intervals based on the type of emergency shower and the environment in which it is located.

The SFS-EN 15154 standard sets the minimum requirements:

- Eyewash stations should be checked weekly to ensure proper water quality and flow.

- Full-body emergency showers must be tested at least once a month.

- An annual service is required for all systems. This includes a thorough check of both the equipment and the water quality. In demanding environments, such as laboratories or high-risk industrial facilities, the maintenance interval may need to be even more frequent.

What regulations apply in Finland?

The maintenance of emergency showers is based on several laws and standards:

- The Occupational Safety and Health Act (738/2002) obliges employers to ensure a safe working environment. Section 45 specifically covers rescue and safety equipment.

- EU Directive 89/654/EEC defines the minimum workplace requirements, including first aid equipment.

- The REACH Regulation requires appropriate safety measures when handling chemicals.

- The SFS-EN 15154 standard series provides detailed requirements for the technical and operational aspects of emergency showers.

In Finland, compliance with these requirements is monitored by occupational safety authorities and Tukes (the Finnish Safety and Chemicals Agency), and insurance companies may also impose additional risk management requirements.